LIFE’S SHORT, CREATE MORE

Transform your ideas into reality with cutting-edge precision. Our most advanced laser systems are designed to empower you to craft, innovate, and achieve like never before.

starting at

$3,000

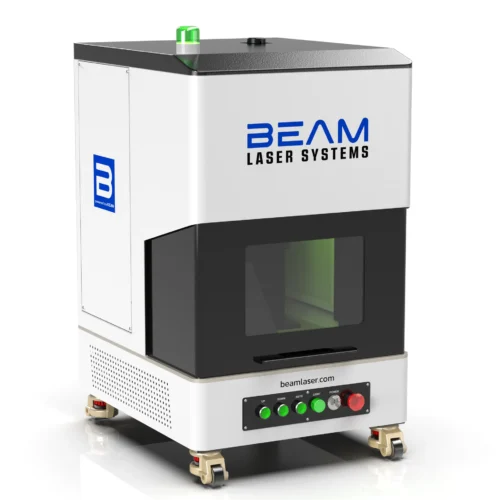

Desktop Galvo Laser

The only thing “small” about our MICRO is its table size, as it can be equipped with the same powerful CO2 lasers as our large format models. The MICRO comes standard with high-speed engraving technology and a moving Y-axis bed for fast, accurate vector cutting. The MICRO laser system is a flexible laser solution, consuming minimal floor space in your facility.

If you’d like to find out how a MICRO laser system can help your business, school or organization, please use our simple contact form or Request a Quote.

Assurance of supply

Assurance of supply

Assurance of supply

Assurance of supply

Assurance of supply

Assurance of supply

Assurance of supply

Assurance of supply

Precision crafted. Built for innovators, by experts.

Precision crafted. Built for innovators, by experts.

A UL certified electrical panel is placed on each laser system which turns on and shuts down components of the laser system. CUL and CE approved machines are available by request.

Two pairs of Laservision laser safety glasses are provided which each CO2 machine. This eyewear is rated OD 6+ @ 9000-11000nm, offering protection from Kern’s full range of CO2 laser systems.

A great all-around processing head equipped with a high-quality optic. The assembly features an assist air which pushes air out of the nozzle, protecting the lens from smoke and debris.

A UL certified electrical panel is placed on each laser system which turns on and shuts down components of the laser system. CUL and CE approved machines are available by request.

Two pairs of Laservision laser safety glasses are provided which each CO2 machine. This eyewear is rated OD 6+ @ 9000-11000nm, offering protection from Kern’s full range of CO2 laser systems.

A great all-around processing head equipped with a high-quality optic. The assembly features an assist air which pushes air out of the nozzle, protecting the lens from smoke and debris.

Precision crafted. Built for innovators, by experts.

The MICRO Laser System is a flexible laser solution, requiring minimal floor space in your facility.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Kern’s CO2 laser format laser systems can be equipped with innovative metal cutting technology. The metal cutting option provides accurate cutting of sheet metals such as stainless steel, mild steel, aluminum, and brass.

High Pressure assist gas, such as oxygen, CDA(clean dry air) or nitrogen, is injected through the metal cutting nozzle. The result is a dross free cut edge that requires little to no deburring.

As the cutting process begins, the height follower tracks the surface of the metal and adjust the nozzle in the z-axis maintaining a constant focus point while the metal is being cut.

To learn more about the Metal Cutting, please watch this video and visit our Metal Cutting page.

Kern’s CO2 laser format laser systems can be equipped with innovative metal cutting technology. The metal cutting option provides accurate cutting of sheet metals such as stainless steel, mild steel, aluminum, and brass.

High Pressure assist gas, such as oxygen, CDA(clean dry air) or nitrogen, is injected through the metal cutting nozzle. The result is a dross free cut edge that requires little to no deburring.

As the cutting process begins, the height follower tracks the surface of the metal and adjust the nozzle in the z-axis maintaining a constant focus point while the metal is being cut.

To learn more about the Metal Cutting, please watch this video and visit our Metal Cutting page.

Kern’s CO2 laser format laser systems can be equipped with innovative metal cutting technology. The metal cutting option provides accurate cutting of sheet metals such as stainless steel, mild steel, aluminum, and brass.

High Pressure assist gas, such as oxygen, CDA(clean dry air) or nitrogen, is injected through the metal cutting nozzle. The result is a dross free cut edge that requires little to no deburring.

As the cutting process begins, the height follower tracks the surface of the metal and adjust the nozzle in the z-axis maintaining a constant focus point while the metal is being cut.

To learn more about the Metal Cutting, please watch this video and visit our Metal Cutting page.

Kern’s CO2 laser format laser systems can be equipped with innovative metal cutting technology. The metal cutting option provides accurate cutting of sheet metals such as stainless steel, mild steel, aluminum, and brass.

High Pressure assist gas, such as oxygen, CDA(clean dry air) or nitrogen, is injected through the metal cutting nozzle. The result is a dross free cut edge that requires little to no deburring.

As the cutting process begins, the height follower tracks the surface of the metal and adjust the nozzle in the z-axis maintaining a constant focus point while the metal is being cut.

To learn more about the Metal Cutting, please watch this video and visit our Metal Cutting page.

Precision crafted. Built for innovators, by experts.

A UL certified electrical panel is placed on each laser system which turns on and shuts down components of the laser system. CUL and CE approved machines are available by request.

Two pairs of Laservision laser safety glasses are provided which each CO2 machine. This eyewear is rated OD 6+ @ 9000-11000nm, offering protection from Kern’s full range of CO2 laser systems.

A great all-around processing head equipped with a high-quality optic. The assembly features an assist air which pushes air out of the nozzle, protecting the lens from smoke and debris.

A UL certified electrical panel is placed on each laser system which turns on and shuts down components of the laser system. CUL and CE approved machines are available by request.

Two pairs of Laservision laser safety glasses are provided which each CO2 machine. This eyewear is rated OD 6+ @ 9000-11000nm, offering protection from Kern’s full range of CO2 laser systems.

A great all-around processing head equipped with a high-quality optic. The assembly features an assist air which pushes air out of the nozzle, protecting the lens from smoke and debris.

Owner Tim Pawelk of “Laser Etch Technologies” roots run deep with Kern Laser Systems. A customer since 1999, Laser Etch currently uses four Kern lasers that have been instrumental in achieving worldwide attention. Such projects included teaming up with renowned Tibetan artist Rinchen Dorgee. Dorgee was instrumental in the creation of the throne the Dalai Lama used during his visit to Minneapolis/St. Paul in May of 2001. The throne was also recently used for His Holiness when he visited Minneapolis this year to celebrate the Tibetan New Year.

Around Minnesota, Tim has also done amazing work. Most notably, his wood etching and engraving can be seen in the Legends Club area located at Target Field, the home of the Minnesota Twins. Baseball fans would recognize Pawelk’s grand slam work located at Target Field, home of the Minnesota Twins. This creative wonder that includes both etching and engraving can be seen in the Legends Club and press box areas of the stadium. Pawelk allows that the Kern Laser Systems has provided him with the needed tools to think outside the box and grow his business through the wide range of capabilities found in a Kern laser.

Laser beam

One safety aspect of laser processing that often gets overlooked is fume removal. When you laser process a material a certain amount of material is vaporized, creating an off-gas. Many materials are safe to process and do not release a hazardous off-gas or release only trace levels which are safe for breathing. However, some materials should not be laser processed at all. It is a good policy to have a Safety Data Sheet(SDS) for all materials that you plan to laser process.

Reviewing SDS sheets is the responsibility of your Laser Safety Officer(LSO) and your LSO should decide which materials are appropriate for laser processing. Please read our Laser Processing Fume Removal blog for a comprehensive view of Kern’s vacuum blower system.

Discover the precision and speed of laser cutting.

Discover the accuracy and artistry of laser engraving.